Anomaly Detection in a Roasting Process Environment

Anomalyse has recently implemented its anomaly detection platform for a UK manufacturing plant producing malt products, monitoring their critical upstream processes, where maintaining optimal operational efficiency and quality is crucial. The production process involves complex machinery and requires the close monitoring of many variables to ensure consistency.

Unexpected process events (e.g., sudden spikes in temperature, unusual pressure variations or deviation from standard flow rates) can lead to product defects, waste product or equipment failure. Anomaly detection has been employed to automatically detect these deviations, allowing for timely interventions to minimise risk and improve overall process control.

Business Objectives:

Early Fault Detection: Identify unusual patterns in real-time to reduce the risk of equipment failure or production defects.

Reduce Unplanned Downtime: Enable predictive maintenance by detecting early signs of malfunction to prevent costly unplanned downtime.

Quality Assurance: Ensure product quality by identifying deviations from normal operational parameters.

Cost Reduction: Minimise waste, rework, and scrap due to undetected anomalies in the manufacturing process.

The Environment:

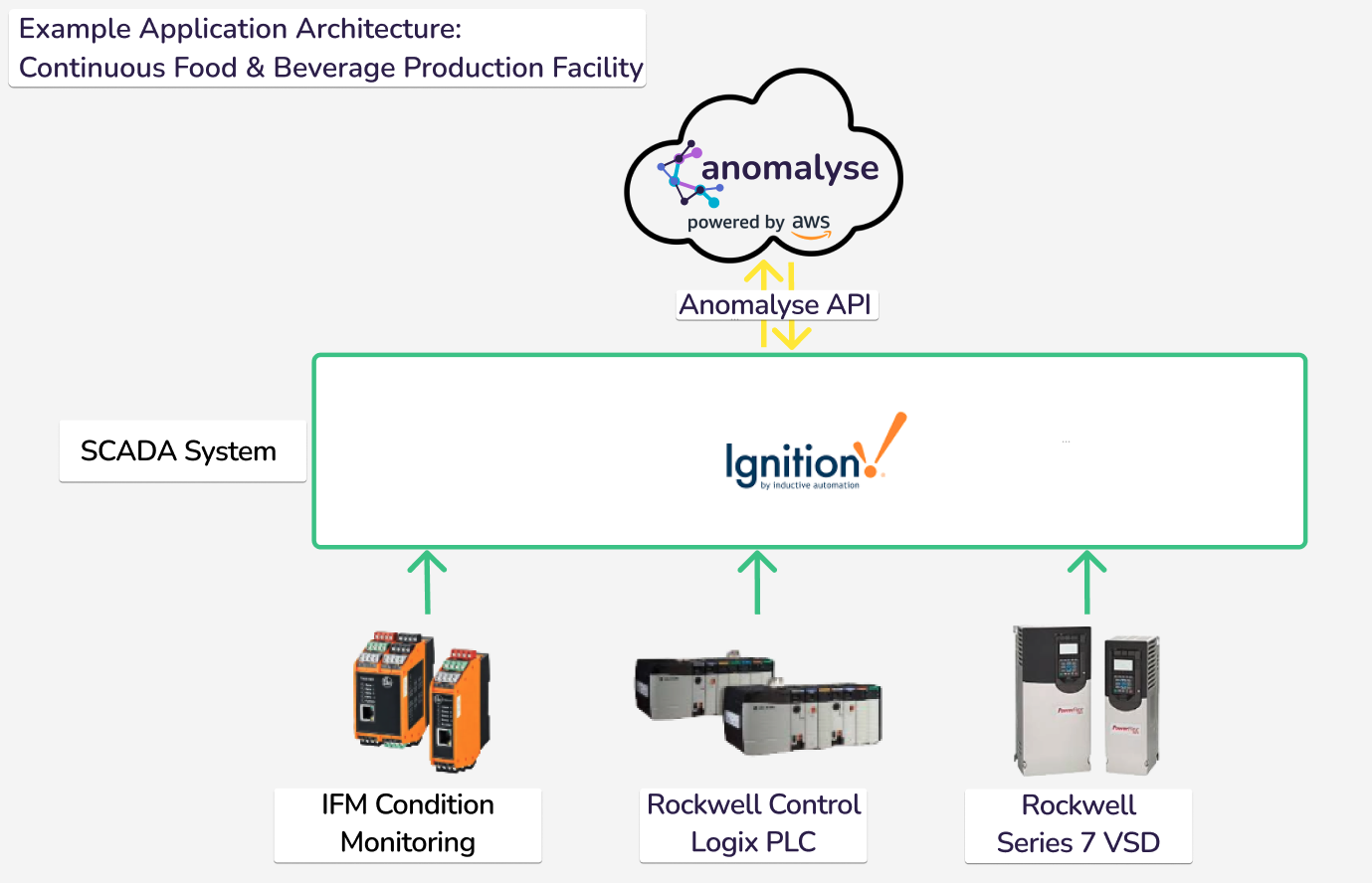

Sensors are connected across the production process via a network of existing PLC’s (e.g., temperature, pressure, humidity and flow rate sensors).

Critical motors are driven via variable speed drives.

Additional condition monitoring sensors have been added.

Historical process data is available for training the anomaly detection models.

The plant's existing IT infrastructure supports real-time data processing and model integration.

API integration for two way data transfer with existing Ignition SCADA system

The Solution:

The anomalyse platform is used to monitor over 30 assets, each using an individually trained a machine learning model.

Each model utilises a multi-parameter approach to gain a contextual view of the corresponding asset.

Anomalies are detected and flagged in real-time, allowing for immediate action or further investigation.

Alerts are generated and sent to the relevant personnel (e.g., process engineers or maintenance teams).

Data points flagged as anomalous are “explained” by the machine learning model, further improving opportunities for improvements in process control.

Continual improvement of the anomaly detection models is provided as well as the opportunity to retrain the models when an asset’s operating conditions are updated.

The Process:

Data Collection: Continuous monitoring of various process variables via existing automation system (e.g., temperature, pressure, speed).

Data Transfer: Raw data is sent to the Anomalyse platform using the API.

Anomaly Detection: Our unique anomaly detection algorithms process the incoming data, identifying deviations in the data from historical operating patterns.

Alert Generation: When a high-magnitude anomaly is detected, the system generates an alert.

Investigation & Action: The relevant personnel (engineers, maintenance staff) receive the alert, which includes an explanation of why the data was deemed anomalous and perform investigations to understand the root cause.

Feedback Loop: Users feedback to Anomalyse on alerts to ensure that alerts are generated only for events of significance and to request retraining of the anomaly detection models when appropriate.

Benefits:

Anomaly detection provides the user with early identification of potential issues, leading to a number of benefits, such as:

Improved Efficiency by reducing reduces unplanned downtime,

Cost Savings through minimising repair costs and material wastage,

Operational Reliability from continuous monitoring leading to more stable processes and better product quality control,

Data-Driven Decisions, real-time insights allow for informed decision making and proactive process optimisation.

Want to learn more, or talk about how anomalyse can help your business improve productivity through Anomaly Detection? Contact sales@anomalyse.io today.